Sample transfer

Changing sample in main chamber

Danger

Turn off the high voltage rack before changing sample!

Caution

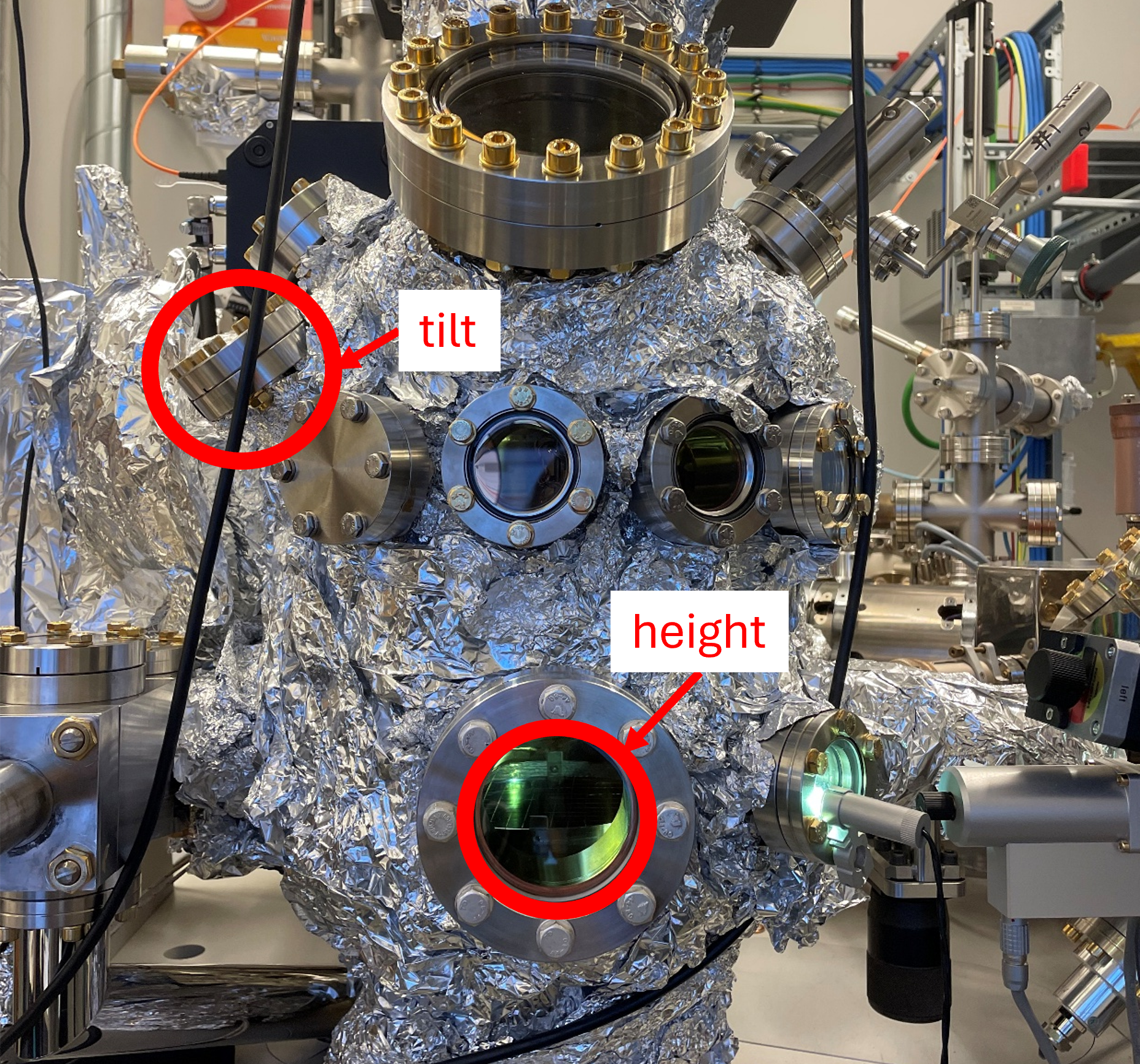

Ensure that the tilt is properly initialized by physically verifying it before adjusting the manipulator head, especially if you plan to insert the sample into storage!

Close the valve to the X-ray beam, turn off the electron gun (-360 V), and either turn off the UV lamp or close its iris entirely, as appropriate.

Initialize the manipulator’s position (X, Y) and tilt to 0 (X, Y, tilt = 0). Double-check the values in both the software and the manipulator head physically. Ensure that the holes are fully exposed and not partially obstructed.

Remove slit and apertures, and double check that the high voltage rack is off!

Before operating the transfer arm, verify the holder’s location in the prep chamber to avoid collisions. Open the valve between the prep chamber and the main chamber, and remember to close it once finished. Always be aware of the transfer arm’s position and any objects in its path, adjusting its orientation as needed.

If the microscope has been aligned, most likely the alignment is good enough for measurements after correcting the sample tilt.

The standby mode generally is FOV = 10 µm and STV = 0V.

Sample insertion from air

Caution

Frequently check the pressure of chambers. After insertion, remember to check the pressure of prep chamber in case of leakage.

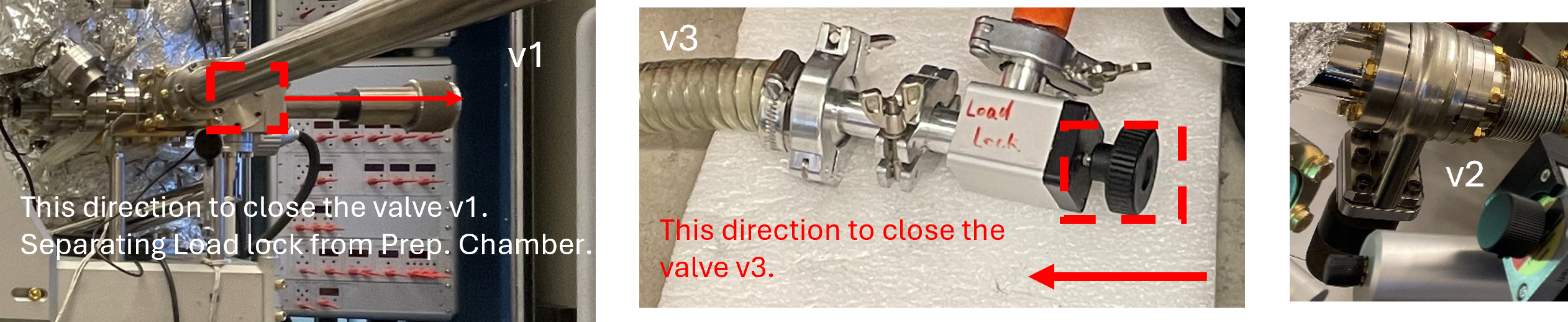

Venting

Check that the valve from load lock to prep chamber (v1), and valve to forepump (v3), and valve from prep chamber to main chamber (v2) are closed.

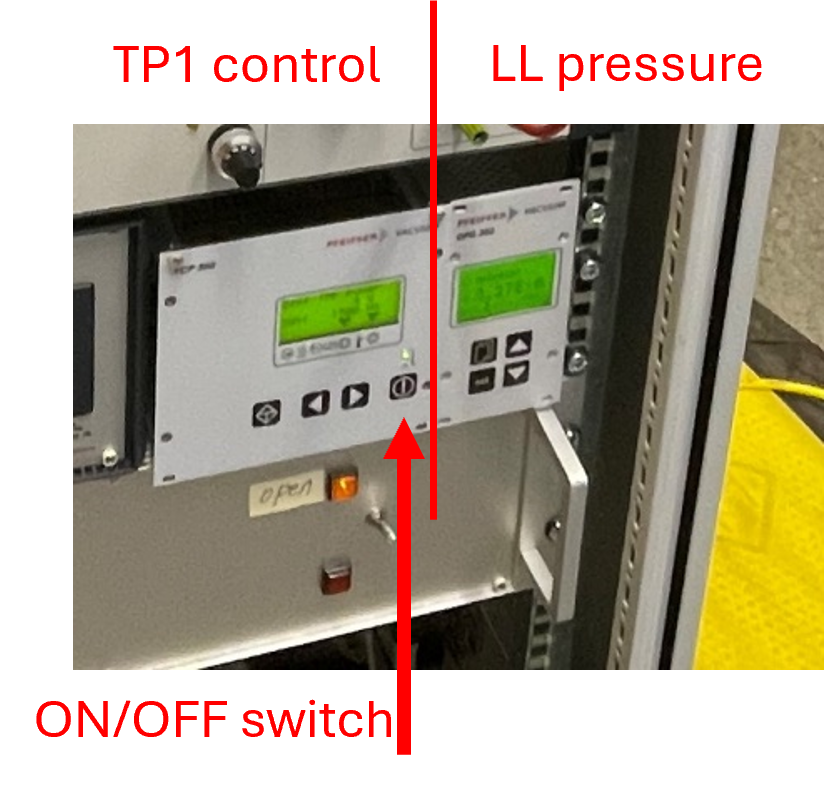

Turn off the small turbo pump (TP1): The green light above the switch will start blinking and speed will decrease from 1500 Hz. Can hear the sound of deaccleration of TP1.

Loose the bolts of load lock but keep them in the holes.

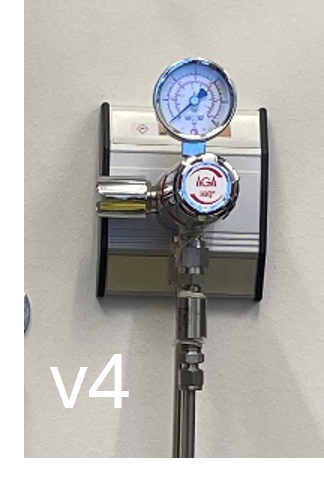

Set the nitrogen gas regulator (v4) around 0.4-0.6 on the low-pressure side (clockwise to open). You will hear the nitrogen flowing through the load lock.

Fully remove the load lock bolts and flange when LL pressure reads 1000 mbar – insert sample (gloves must on) – stop the nitrogen flow via v4 – close the Load lock bolts (one up right, one down left) and flange. Hand tighten the two bolts instead of using a wrench, to avoid over-tightening.

Pumping down after sample insertion

Slowly open valve to forepump (v3) and switch on small turbo pump TP1. Hear the noise from forepump pumping.

Slowly close v3 when reads 50 mbar on load lock pressure.

Wait until the load lock pressure reads at least 3x10^-6 mbar to transfer the sample into prep chamber. This might take 15-30 minutes.

Leave sample in prep chamber to degas. Close v1 to separate load lock and prep chamber.

Sample insertion to prep chamber

Carefully observe the position of the holder in the prep chamber, as the motor does not have an auto-step function. The scale should reach 286 to accommodate the sample.

Check the height and tilt of the sample through the two marked windows before insertion.

The transfer must be smooth. If any resistance is felt, stop immediately, as this indicates a misalignment. Do not apply force greater than finger force.

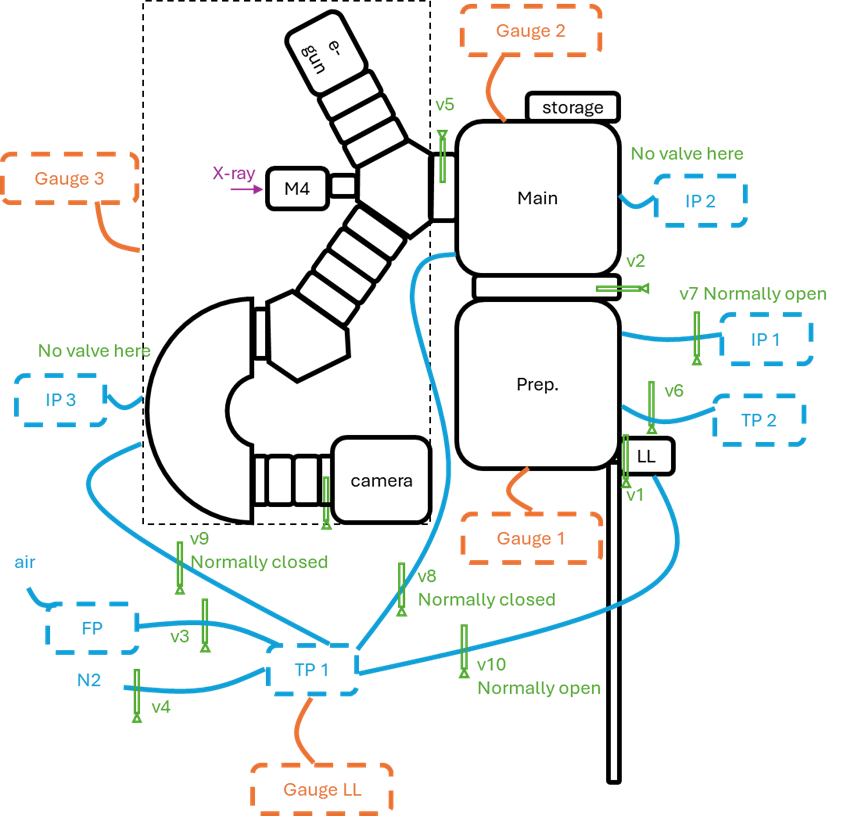

Schematic Layout of the UHV System

Vacuum suitcase connected to the load-lock

For air-sensitive samples, MAXPEEM offers the option of transferring the sample in argon. One needs to book a chemistry lab with a glovebox (e.g. D3) https://lab-booking.maxiv.lu.se/

Transfer the suitcase, sample cartridge, sample(s), etc. into the glovebox, using the large antechamber

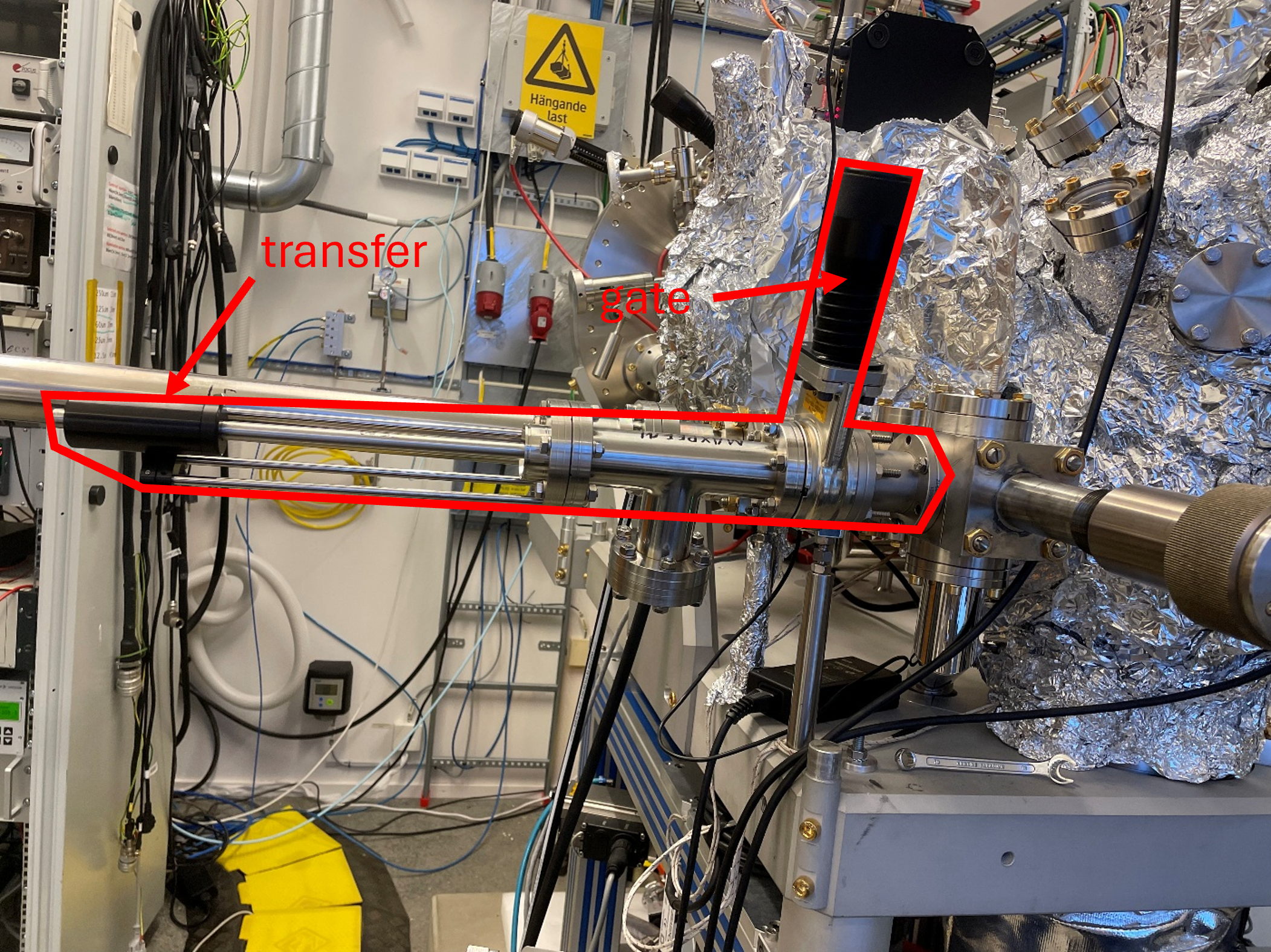

Figure 1. Photo of the suitcase connected to the load lock.

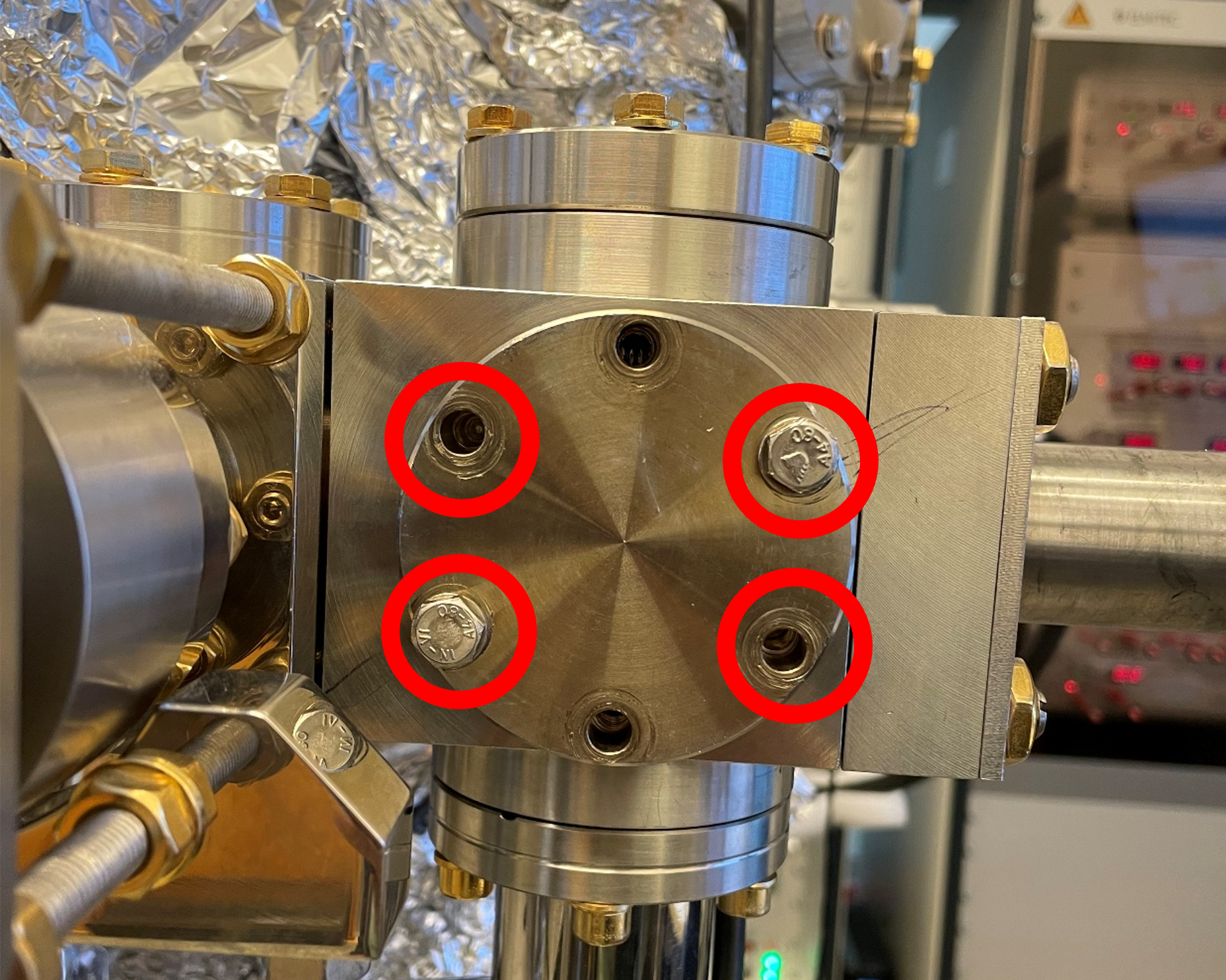

Figure 2. Four screws are needed to fix the suitcase to the load lock.

Vent the load lock, remove the flange and keep the o-ring in. Handle with gloves at all times.

Stop the nitrogen flow.

(two-person operation) Hold the suitcase and align it to load lock. Secure it with four screws. Tighten the screws using a wrench with finger force only (do not overtighten).

Pump down the load lock normally and slowly open the gate of suitcase when the pressure reach 10^-2 level. Transfer the sample into load locak and close the gate.

Transfer the sample into prep chamber when the pressure reads 3x10^-6 mbar.

Vacuum suitcase connected to the prep chamber

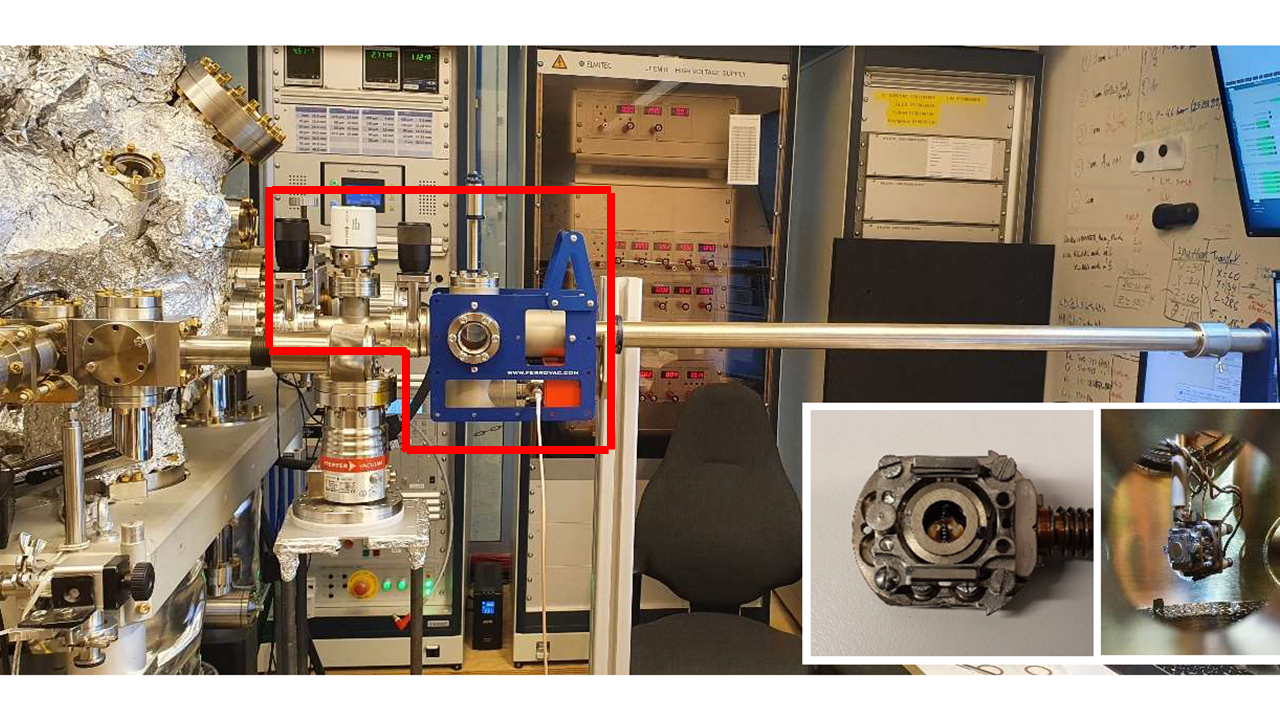

Figure 2. Photo of the Ferrovac UHV suitcase connected to the prep chamber. The inset shows the Elmitec-Omicron adaptor.

In the prep chamber, an Omicron flag-type sample plate can be transferred using an Omicron-Elmitec adaptor via a Ferrovac UHV suitcase.

Mount the sample on sample holder

Install the cartridge in the aluminum holder.

Loosen the four M2 screws holding the sample down.

Remove the sample cover

Remove the sample

Install the new sample

Install the sample cover

Fix the cover with the four screws (suggestion: tighten the screws in an X pattern)

Caution

The tilt on the manipulator can only be adjusted up to +/- 2 degrees. Mount the sample onto the cartridge as flat as possible.